A word from the coordinator

I welcome you to the first NanoPack e-newsletter. The NanoPack project aims to develop state-of-the-art antimicrobial packaging solutions based on natural nanomaterials to extend the shelf-life of perishable foods and reduce waste. I am excited to share with you progress we made during the first year of the project.

We started our first year with a fruitful kickoff meeting in Ghent, Belgium to officially commence the project. We continued with extensive efforts to share our knowledge and expertise in joint work and experiments at different partners facilities. We are learning from each other so much as this complex multidisciplinary project integrates nanomaterials, polymers engineering, food microbiology, regulation aspects, safety, environment, consumer and market studies. Our innovation group is learning the effects of consumer behavior and is working towards the creation of a business plan for the final packing product. We had a fully engaged and productive year.

I am amazed to see how much progress we made in 12 months and I am looking forward to the coming years and the continuations of the fruitful collaboration between our partners. I am confident that our committed team will generate solutions for extending food shelf life by using novel smart antimicrobial surfaces in active food packaging products.

Nanopack in a nutshell

NanoPack is a 3-year EU funded project aimed at developing and demonstrating a solution for extending food shelf life by using novel antimicrobial surfaces applied in active food packaging products. Intelligent and active packaging are revolutionizing the role of food packaging, from being a passive container, to having a functional role in increasing food shelf-life and monitoring freshness. Read more here.

The Nanopack technology consists in the encapsulation of essential oils with a naturally-occurring antimicrobial activity into Halloysite nanotubes (HNTs), which are subsequently mixed with polymers to make packaging films. What makes Nanopack unique is that antimicrobial agents are released as a vapour from the packaging materials into the headspace, therefore they can sanitize both the product surface and the headspace.

NanoPack will prolong shelf life, thus improving food safety and reducing food waste. By doing so, Nanopack will be directly contributing towards the European Parliament’s 2030 goals to cut the 88 million tonnes of food waste per year in half by 2030. NanoPack will also address scientific, technological, economic, safety and regulatory challenges to ensure that consumers eventually will be able to benefit from this novel packaging. Read more here.

Searching the best film composition

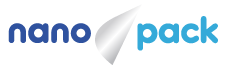

Since the kick-off of the project, the Science Team has been working hard to scale up the loading of antimicrobial oils into the halloysite nanotubes for film production. Several kilograms of first generation HNTs loaded with the essential oil carvacrol have been successfully produced.

The Packaging team is working on the development of the final packaging film that will be used in food to extend its shelf life. The antimicrobial film is made by mixing the loaded HNTs with a polymer of choice.

Researchers are looking into the best polymer to encapsulate the loaded HNTs, the material structure and amount of essential oils loading to achieve the highest organoleptic performance possible. So far, the most successful combinations consists in polyethylene (PE) and polypropylene (PP) based multi-layer film structures as well as an extrusion coated aluminum foil loaded with carvacrol. Read more here.

Nanopack active packaging increases bread shelf-life by 3 weeks

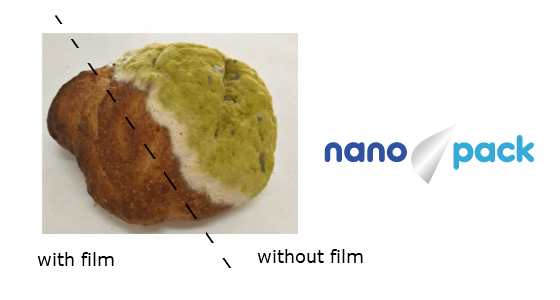

Additive free-bread was inoculated with mould spores and covered with Nanopack film (left side) or not covered (right side).

The preliminary Nanopack film was tested in four food types: fresh meat, cheese, bread and salmon. A first round of antimicrobial efficacy tests has shown how NanoPack film inhibits mould growth on food-additive free bread. Breads that were inoculated with relevant-mould spores and packed with NanoPack’s innovative film insert had no mould growing for up to 27 days post packaging, showing that NanoPack active packaging can extend bread shelf life by 3 weeks.

In the upcoming year, the Science team will focus on optimizing the film-making process. The antimicrobial raw material, composition with polymer and film configuration. Several film configurations will be tested to address different types of food packaging. Experiments with real food packaged in these novel films will also be performed. Read more here.

Consumers’ and acceptance of novel packaging technologies

To be successful, Nanopack must match the market and user needs in a cost-effective manner while offering advantages over existing active packaging in terms of safety and performance. However, this is not enough. It is also important that consumers readily accept Nanopack technology. To have a better insight into consumers and retailers’ perception, a study was carried out with 10 focus groups with consumers and 10 in-depth interviews with retailers across five countries (Ireland, Denmark, Italy, Spain, and China). The outcome of this study will hopefully help us understand how is Nanopack technology perceived and what are the main barriers for its acceptance.

Meeting in Aarhus to discuss regulatory requirements for NanoPack

The Regulatory Task Force has met in January in Aarhus to discuss regulatory requirements for Nanopack to be successfully introduced in the market. Due to their function as preservatives, the essential oils used in Nanopack are considered food additives. Therefore, their use in food packaging need to be approved under EU legislation for active packaging materials.

The Regulatory Task Force has met in January in Aarhus to discuss regulatory requirements for Nanopack to be successfully introduced in the market. Due to their function as preservatives, the essential oils used in Nanopack are considered food additives. Therefore, their use in food packaging need to be approved under EU legislation for active packaging materials.

Preliminary results from focus groups and interviews with retailers across 5 countries show that there are no strong negative reactions towards the Nanopack technology and that the benefits promised by the technology are generally valued by both consumers and retailers. However, there are certain concerns that need to be accounted for and the team will be working to find ways to break these down.

NanoPack organized an Hackathon at the AIPIA Congress 2017

The NanoPack project was prominently represented at the AIPIA Congress 2017, which took place on 2-3 November 2017 in Amsterdam. During the event, a Hackathon was also organised together with the Active & Intelligent Packaging Industry Association around the topic ‘Acceptance of Nanotechnology’. The hackathon brought together delegates from industry, academia, and consultancies who concluded that increased communication about the basics and benefits of nanotechnology is needed and the time to start educating the public about what nanotechnology is now. Read more here.

NanoPack at AnugaFoodTec 2018

The NanoPack project was successfully presented at AnugaFoodTec 2018. Visitors not only had the chance to meet the team behind the project, but also to see prototypes of the antimicrobial film technology. Read more here.

Join NanoPack Stakeholder Forum

A NanoPack LinkedIn group has been established as a Stakeholder Forum, where representatives of opinion leaders, regulators, food producer associations, food industry, retailers and consumer organisations are invited to engage in discussions about active packaging, nanotechnology, consumer perceptions and the developments taking place within the NanoPack project. For more information or requests to join click here or contact Dr. Hayley Every (h.every@effost.org).