One of NanoPack’s goals is to produce an antimicrobial film that could be used for food packaging to prevent spoilage, thus increasing food shelf-life and reducing food waste. But what has been achieved one year from the start of the project?

The main achievement was the successful scale-up for the film production.

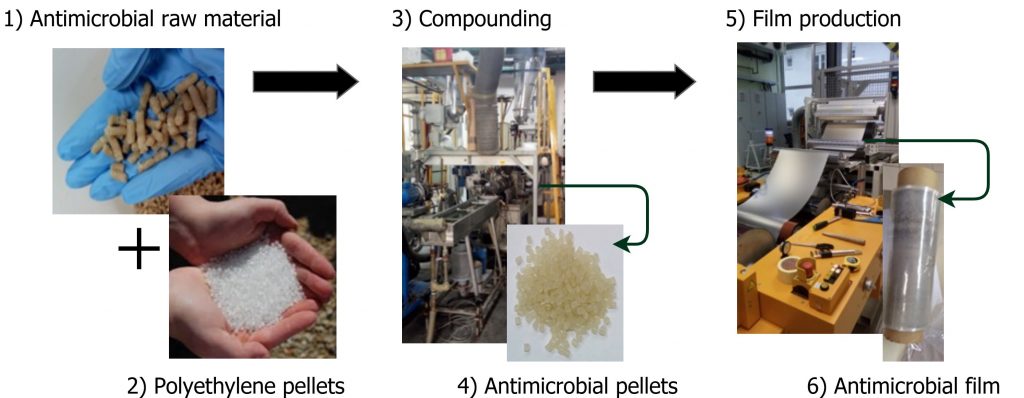

This was possible thanks to the joined efforts of the different partners of the Packaging Working group, which contributed with their expertise to the film-making chain. The Technion (Israel) and Bio base Europe plant (BBEPP, Belgium) were involved in technology transfer and production of antimicrobial raw material (1). Next, the antimicrobial raw material was compounded with polyethylene (2,3) by Carmel Olefins (Israel) to produce antimicrobial pellets (4). Finally, Constantia flexibles (C-Flex, Austria) produced the plastic films (5,6), which Technion tested for their antimicrobial properties on foodstuff.

The antimicrobial raw material produced at BBEPP showed almost no loss of antimicrobial agent during processing, including compounding and film production. This is a huge advantage, since it maximizes the antimicrobial effect of the film packaging on the foodstuff. This achievement was possible thanks to the joint efforts of BBEPP, who carefully chose the amount of antimicrobial raw material to use in order to maximize the antimicrobial effect, and Carmel Olefins, who investigated the best compounding parameters to achieve homogeneous plastic pellets.

In C-Flex, film production parameters were also set in order to yield a film of very good quality. Several films differing in thickness, production technique and number of inner layers were produced. Many of them showed an antimicrobial activity, and they were used by Technion during antimicrobial tests.

Following the successful first year, the second year of the project will focus on optimizing the film-making process. In the upcoming months, the antimicrobial raw material and several film configurations will be tested to address different types of food packaging. Experiments with real food packaged in these novel films will also be performed.

No need to say that the goal of decreasing food waste is closer than ever!